IQ Easy Platform Products

IQ EASY PLATFORM

Overview

Full control of static electricity in your production process. thanks to the IQ Easy Platform

You or your end customer expects a very high quality product with very little, or no, static charge.

A disrupted process and damaged material are costing you lots of money and cause dissatisfied customers.

What is the possible ‘monster’ that always throws a spanner in the works?

Static electricity!

Even very low static charges in your production process can cause problems in processing all kind of products.

You can breathe a sigh of relief, because you can now eliminate the static electricity to a desired level and putting the static charges to your hand with help of the IQ Easy platform!

Read on soon so you can discover how this static control system can help you!

Possible problems with static charges in your manufacturing process

There are many problems possible that are related to static electricity, for example:

- Workers get static shocks

- A disrupted process

- Damaged material through static electricity

- Your customer has problems with your material

- But it can be even worse..

Fire or an explosion through high static charges!

Meet high demands through intelligent control of static electricity

Individual static electricity equipment can help you already a long way. Several Simco-Ion anti-static devices can reduce or eliminate static electricity in your production process, charging equipment can help you with static charging/static bonding etcetera..

So imagine what a fully integrated static control system can do for you!

Fully control all parameters and let devices interact with each other to optimise efficiency

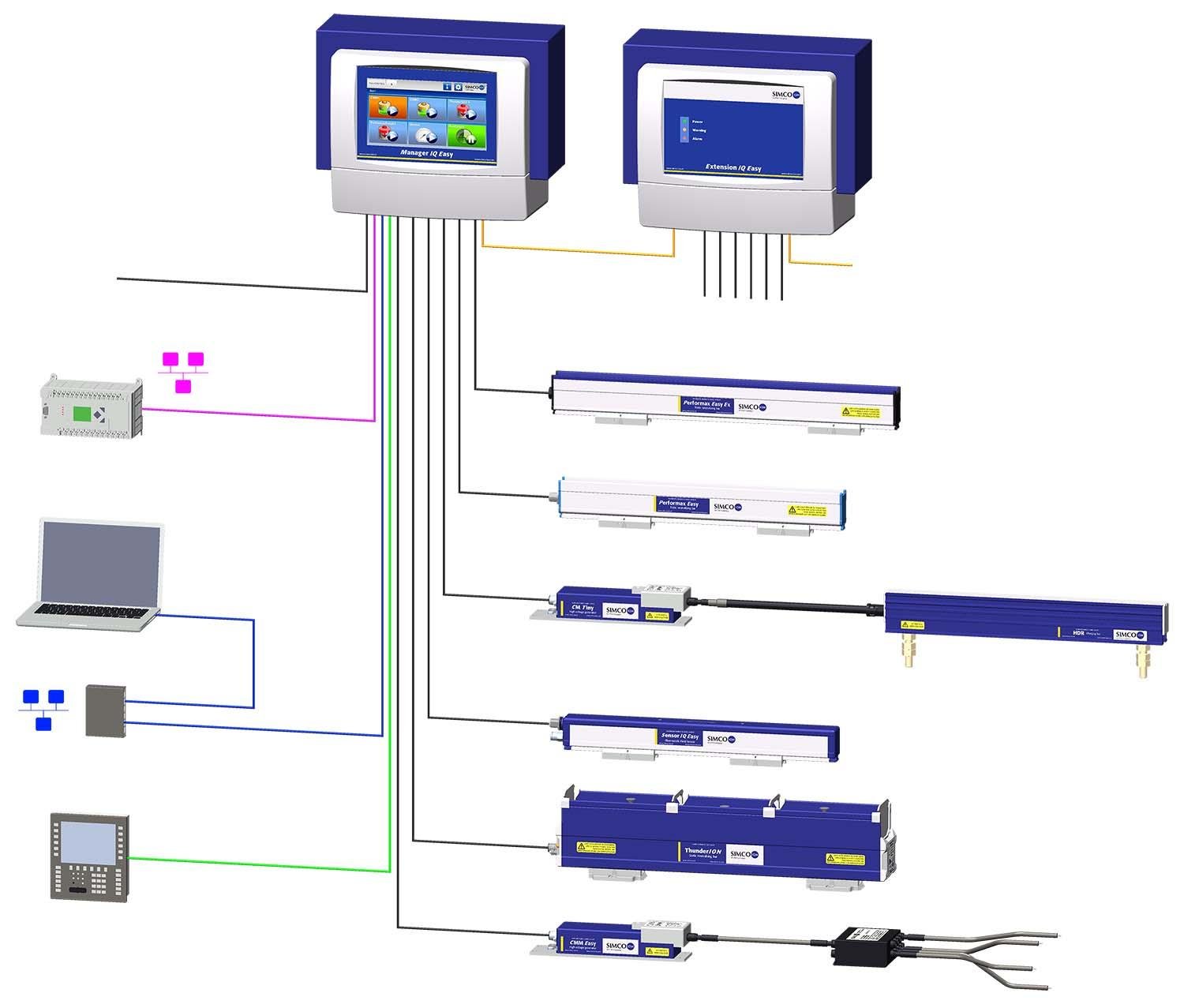

The IQ-Easy Platform connects up to 30 (anti) static devices into a network via the Manager IQ Easy. An unique concept that makes it possible to fully control all parameters and let devices interact with each other to optimise efficiency.

No cable ‘spaghetti’

The IQ Easy system is unique because all devices form a system and not as before all operate separately, so no need for additional cables and individual power supplies (no cable ‘spaghetti’)!

The lowest possible achievable residual static charges

When you add a Sensor IQ Easy bar to your IQ Easy Platform, it monitors the residual web charge across the web with up to 16 measuring sections. This will enable the anti-static devices to read the measured data and optimise the settings to reach the desired static level (this is called CLFB, Closed Loop Feedback).

Production failures and production stops will be reduced.

Quality assurance

You can find back all data and action logs.

No surprise machine stops due to defective static control equipment anymore!

An advantage of the IQ devices instead of the classic static devices is that you will get a warning when there is something wrong with a device so that you can intervene on time. The warnings and alarms will give you the chance to plan the maintenance or replacing of equipment before full break down.

Manager IQ Easy Introducing a new level of static control; the heart of the new IQ Easy platform is the Manager IQ Easy. It comprises of a Control unit with a 7'' LCD touch screen, provides information from all the connected devices and makes it easy to change and monitor status and parameters. Up to 6 IQ devices can be directly connected to the Manager IQ Easy. The 24V DC power distribution is routed via the Manager, so no extra cables! This makes the connection of a device even easier than connection to a single desktop power supply.

-

- 7” full colour touch screen.

- Information is colour coded.

- Controls up to 30 devices.

- Connection up to 6 devices.

- Analogue & digital inputs and outputs.

- Serial fieldbus interfaces.

- Ethernet interface.

- USB interface.

The LCD display is beautifully styled and clearly organised giving the operator an immediate overview and status of the system. All information is colour coded and visible from a long distance.

Blue: The device is operational and running.

Green: The device is operational, but in standby mode.

Orange: Notice, one or more devices need attention e.g. cleaning is required.

Red: Alarm, a device has a fault or parameter has exceeded the alarm level.

Grey: No device is connected.

SPECIFICATIONS

|

Supply voltage |

100 – 240 V AC nom. (90 – 305 V AC) |

|

24 V DC 3/+10% |

|

|

Frequency |

50 – 60 Hz nom. (47 – 63 Hz) |

|

Max power consumption |

300 W (100 – 240 V AC version) |

|

360 W (@15 A) (24 V DC version) |

|

|

Purpose |

Industrial, indoor use |

|

Protection class |

IP52 |

|

Operating temperature |

0 – 55 °C |

|

Installation |

Free of dust and vibration |

|

Device output 100-240 V AC version |

24 V DC 3 A max. per port, total max. 9 A |

|

Device output 24 V DC version |

24 V DC 3 A max. per port, total max. 13 A |

|

Machine I/O |

|

|

Digital inputs |

10-30 V 25 mA max. |

|

Analog input |

0-10 V 0,6 mA / 0- 20 mA / 4- 20 mA |

|

Digital outputs |

OE/OC 24 V DC nom. Max. 30V 25 mA |

|

USB |

3x USB 2.0 |

|

Ethernet |

1x RJ45 8-pin connector |

|

Fieldbus (optional) |

1x Anybus interface |

|

Weight |

5,5 kg (100 – 240 V AC version) |

|

3,9 kg (24 V DC version) |

Literature

Product Brochures

https://www.simco-ion.co.uk/our-products/iq-easy-platform/manager-iq-easy/#

Company Documents